Understanding the Basics

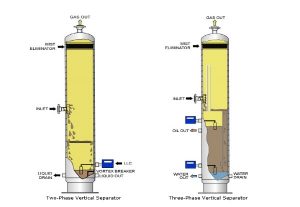

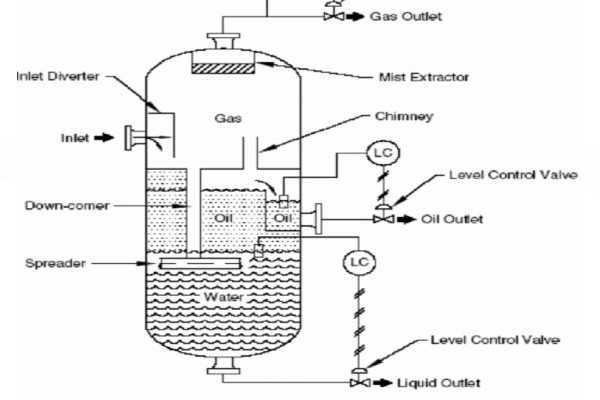

Vertical Three-Phase Separator with Interface Control

A three-phase separator is a crucial piece of equipment in the oil and gas industry, designed to separate a mixture of oil, gas, and water into its individual components. The vertical three-phase separator, equipped with interface control, is a particularly efficient design for maintaining optimal separation efficiency and preventing liquid carryover.

Pictured above: Vertical Three-Phase Separators with Interface Control

The Role of Interface Control

Interface control is a mechanism that regulates the interface between the liquid and gas phases within the separator. This is typically achieved through the use of level transmitters and control valves. By maintaining the correct liquid level, interface control helps to prevent liquid carryover into the gas outlet and ensures efficient separation.

How Does It Work?

- Inlet: The mixture of oil, gas, and water enters the separator.

- Separation: As the mixture enters the vessel, the heavier liquids (oil and water) settle to the bottom, while the lighter gas rises to the top.

- Interface Control: Level transmitters continuously monitor the interface between the oil and water layers.

- Control Valve Adjustment: Based on the level transmitter readings, control valves adjust the flow rates of the oil and water outlets to maintain the desired interface level.

- Gas Outlet: The separated gas exits through the gas outlet at the top of the separator.

- Liquid Outlets: The separated oil and water are drawn off through their respective outlets.

Advantages of Vertical Three-Phase Separators with Interface Control

- Efficient Separation: Interface control ensures optimal separation efficiency by maintaining the correct liquid levels.

- Reduced Liquid Carryover: By preventing liquid carryover into the gas outlet, interface control improves gas quality.

- Improved Liquid-Liquid Separation: Precise control of the interface level enhances the separation of oil and water.

- Flexibility: Can be customized to accommodate various flow rates, pressures, and liquid-gas ratios

Key Considerations for Design and Operation

- Separator Size: The separator must be adequately sized to handle the expected flow rates and liquid-gas ratios.

- Interface Control System: The interface control system, including level transmitters and control valves, should be reliable and accurate.

- Inlet and Outlet Nozzles: The inlet and outlet nozzles should be properly sized and positioned to minimize turbulence and maximize separation efficiency.

- Internal Components: The internal components, such as baffles and mist eliminators, should be designed to optimize separation and minimize pressure drop.

- Maintenance: Regular maintenance is essential to ensure optimal performance and prevent equipment failures.

By understanding the principles of operation and the key design considerations, engineers can select and design vertical three-phase separators with interface control to meet the specific needs of oil and gas production facilities.