Understanding Water-Tube Boilers: Design, Applications & Inspection Essentials

Explore how water-tube boilers work, their advantages, and key inspection focus points to stay ASME- and NBIC-compliant.

What Are Water-Tube Boilers?

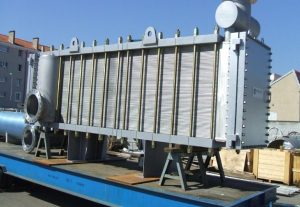

A water-tube boiler is a type of boiler where water circulates inside the tubes, and hot combustion gases flow around the outside of those tubes. This design is ideal for high-pressure applications and large steam outputs, making it the go-to choice for power plants, refineries, chemical processing, and other heavy-duty industries.

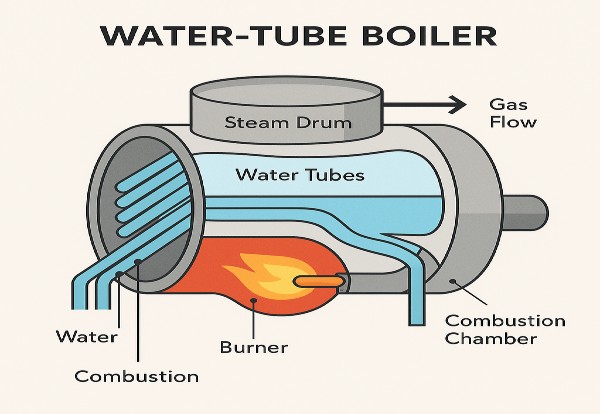

Pictured above: Water-Tube Boilers

How Water-Tube Boilers Work

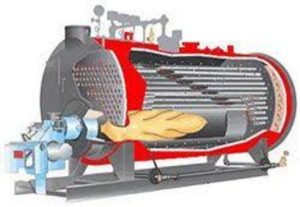

The basic operation flips the script on fire-tube boilers. Instead of hot gases flowing through tubes in a water-filled shell, water-tube boilers have water flowing through tubes while hot combustion gases flow over them.

Key Components:

- Drum (steam & mud drums) – collects steam or sediment

- Water tubes – carry feedwater and generate steam

- Headers – distribute water to the tubes

- Burner & combustion chamber – heat source for gas flow

- Economizer / Superheater (optional) – improves efficiency

This design makes it easier to handle high pressures and rapid load changes.

Advantages of Water-Tube Boilers

✅ Higher pressure capacity — ideal for industrial steam generation

✅ Faster response time to load changes

✅ Smaller water content — reduces explosion risk

✅ Modular configurations for tight or customized installations

✅ Efficient heat transfer due to tube surface area

Key Inspection Areas

Water-tube boilers require diligent inspection and maintenance due to their complex structure and high-pressure service.

- Internal inspection of steam drum and mud drum

- Tube scaling or erosion — especially near bends

- Cracking in rolled tube ends

- Welded joints on headers and nozzles

- Drainage and venting provisions

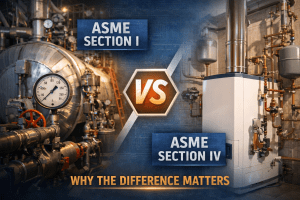

- Compliance with ASME Section I or Section IV depending on service

- NBIC repair/alteration records

Inspections may require disassembly, borescope access, or ultrasonic thickness testing depending on operating conditions.

Code Compliance

Most high-pressure water-tube boilers fall under ASME Section I (Power Boilers). For repairs, alterations, and rerating, compliance with the NBIC is essential — and that’s where we come in.

Should You Use a Water-Tube Boiler?

If you’re operating in a high-pressure environment, have large steam demand, or need responsive performance — water-tube boilers may be the better fit over fire-tube systems. They’re built for power and performance, but that also means more complexity in inspections and repairs.

Whether you’re commissioning a new boiler, updating documentation, or planning a repair — contact our Partner site J Lowry, LLC. They have the tools and experience to make sure your water-tube boiler is code-compliant and safe.

👉 www.jlowryllc.com

📞 281-995-0552