Produced well fluids consist of various amounts of oil, water, natural gas, and sediment. The first step in oil and gas production is to split the flow up into its individual components with a separator.

A three-phase separator uses gravity to separate produced well fluid into gas, oil, and water phases. Installation of these vessels occurs near the wellhead, and they come in horizontal and vertical configurations.

Pictured above: Three-Phase Separator

4 Types Of Three-Phase Separator Vessel Design

Separator vessel design is a crucial consideration for oil and gas producers trying to separate valuable resources from disposable ones. Produced well fluid consists of different ratios of oil, water, natural gas, and sediment. Horizontal and vertical three-phase separators split that emulsion into three individual components.

Horizontal vs. Vertical Three-Phase Separators: A Comparative Analysis

Three-phase separators are crucial equipment in the oil and gas industry, used to separate produced fluids into their constituent phases: oil, gas, and water. Both horizontal and vertical configurations are commonly used, and the choice between them depends on various factors like flow rates, pressure, and specific application requirements.

Ultimately, the selection of a horizontal or vertical three-phase separator involves a careful evaluation of these factors and the specific needs of the application. Consulting with experienced engineers and considering industry best practices is crucial to ensure optimal performance and safety.

Key Factors for Selection

- Flow Rates: High liquid flow rates favor horizontal separators, while high gas flow rates favor vertical separators.

- Pressure: High-pressure applications may require specific design considerations for both types.

- Space Constraints: Vertical separators are often preferred in space-constrained areas.

- Liquid Slug Frequency: Horizontal separators are better suited for handling frequent liquid slugs.

- Operating Conditions: Factors like temperature and corrosion can influence the choice of material and design.

Horizontal Three-Phase Separator

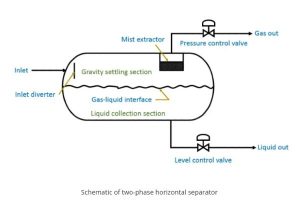

In a horizontal three-phase separator, fluid enters the vessel through an inlet, and immediately hits an inlet diverter. This sudden impact provides the initial separation of liquid and vapor and begins the gas-oil separation process.

In the liquid collection section of the vessel, the oil and emulsion separate, forming a layer (or “pad”) above the free water. A weir maintains the oil level, while an interface liquid level controller maintains the water level. The oil spills over the top of the weir, and then a level controller, which operates the oil dump valve, controls its level.

An interface level controller also senses the height of the oil-water interface. This controller signals another dump valve to release as much water from the vessel as is needed to maintain the oil-water interface at the pre-determined height.

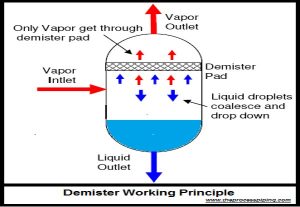

Meanwhile, gas rises to the top of the separator. It flows horizontally and exits through a mist extractor to a high-pressure control valve, which maintains constant vessel pressure.

Pictured above: Horizontal Three-Phase Separator

Advantages Of A Horizontal Three-Phase Separators

- Efficient liquid-liquid separation: The horizontal design provides a larger liquid-liquid interface, promoting efficient separation of oil and water.

- Lower pressure drop: The longer horizontal path reduces pressure loss across the separator.

- Better handling of liquid slugs: Can handle high liquid flow rates and liquid slugs more effectively.

Disadvantages Of A Horizontal Three-Phase Separators

- Larger footprint: Requires more space for installation.

- More complex piping: Can be more complex to install and maintain due to the horizontal orientation.

Vertical Three-Phase Separator

In a vertical three-phase separator, the flow enters the vessel through a side inlet as well and is immediately met by an inlet diverter. This impact begins the separation process. A downcomer transmits the liquid through the oil-gas interface. A chimney equalizes gas pressure between the lower section and the gas section.

Pictured above: Vertical Three-Phase Separator

Advantages Of A Vertical Three Phase Separators

- Smaller footprint: Requires less space for installation, making them suitable for confined areas.

- Simpler design: Typically has a simpler design compared to horizontal separators.

- Better gas-liquid separation: The vertical orientation promotes efficient gas-liquid separation.

Disadvantages Of A Vertical Three Phase Separators

- Lower liquid-liquid separation efficiency: May not be as efficient as horizontal separators for separating oil and water.

- Higher pressure drop: Can have a higher pressure drop, especially at high gas flow rates.