A Comparative Analysis

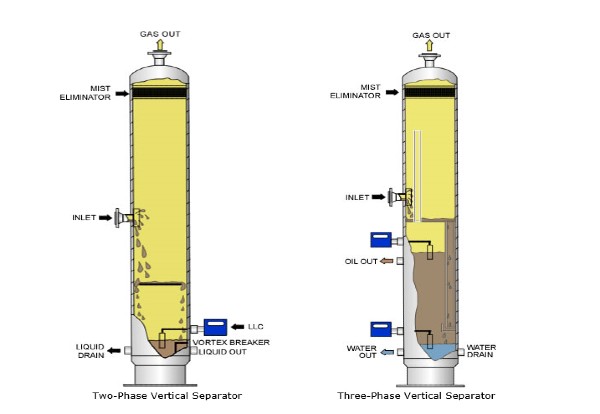

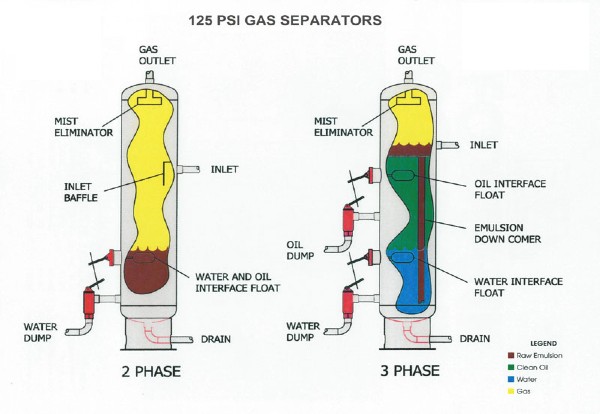

The key difference between a two-phase separator and a three-phase separator is the number of phases they are designed to separate. While a two-phase separator separates gas and liquid, a three-phase separator can handle gas, oil, and water. The design and internal components of the separators may vary accordingly to accommodate the different phases and their interactions. A three-phase separator is similar to a two-phase separator except that it has additional baffles and level controllers, one to drain water, and another is to drain oil.

Pictured above: Two-Phase Separator Vs Three-Phase Separator

Two-Phase Separator

A two-phase separator is designed to separate a mixture of gas and liquid into two distinct phases: gas and liquid. It is typically used when there are only two phases present, such as separating natural gas from liquid hydrocarbons or separating gas from oil. The primary function of a two-phase separator is to allow the gas phase to rise to the top and be separated from the liquid phase, which collects at the bottom. The separated gas is then sent for further processing or transportation, while the separated liquid is either stored or processed separately.

Key Components of a Two-Phase Separator:

- Inlet: The point where the fluid mixture enters the separator.

- Gas Outlet: The outlet for the separated gas phase.

- Liquid Outlet: The outlet for the separated liquid phase.

- Mist Eliminator: A device that removes liquid droplets from the gas stream.

A three-phase separator is designed to separate a mixture of gas, oil, and water into three distinct phases: gas, oil, and water. It is used when all three phases are present and need to be separated, such as in oil production facilities or oil-water-gas separation systems. The primary function of a three-phase separator is to separate the gas phase from the liquid hydrocarbons (oil) and the water phase. The gas rises to the top and is collected, while the oil and water phases are separated based on their density. The oil is collected in the middle layer, while the water settles at the bottom.

Key Components of a Three-Phase Separator:

- Inlet: The point where the fluid mixture enters the separator.

- Gas Outlet: The outlet for the separated gas phase.

- Oil Outlet: The outlet for the separated oil phase.

- Water Outlet: The outlet for the separated water phase.

- Mist Eliminator: A device that removes liquid droplets from the gas stream.

- Interface Control: A system that maintains the interface between the oil and water layers.

Key Differences Between Two-Phase and Three-Phase Separators

Feature |

Number of Phases Separated |

Complexity |

Component Count |

Cost |

Two-Phase Separator |

2 (gas and liquid) |

Simpler design |

Fewer components |

Generally less expensive |

3 (gas, oil, and water) |

More complex design |

More components |

Generally more expensive |

Key Differences Between Two-Phase and Three-Phase Separators

Features

- 1. # of Phases Separated

- 2. Complexity

- 3. Complexity

- 4. Cost

Two-Phase Separator

- 1. 2 (gas, liquid)

- 2. Simpler design

- 3. Fewer components

- 4. Less expensive

Three-Phase Separator

- 1. 3 (gas, oil, water)

- 2. More complex design

- 3. More components

- 4. More expensive

Pictured above: 125-psi-2 vs 3-phase Separators

Choosing the Right Separator

The choice between a two-phase and three-phase separator depends on the specific application and the characteristics of the fluid stream. Key factors to consider include:

- Fluid Composition: The presence of water in the fluid stream necessitates a three-phase separator.

- Flow Rate: The flow rate of the fluid stream can influence the size and design of the separator.

- Pressure and Temperature: The operating conditions can affect the separator’s design and materials.

- Regulatory Requirements: Environmental regulations may dictate the type of separator required.

It’s worth noting that there are also other variations of separators used in the industry, such as four-phase separators that handle additional components like sand or solids. The specific separator used depends on the composition of the fluid mixture and the separation requirements of the process or facility.

By carefully considering these factors, engineers can select the appropriate separator to ensure efficient and effective separation of the fluid mixture