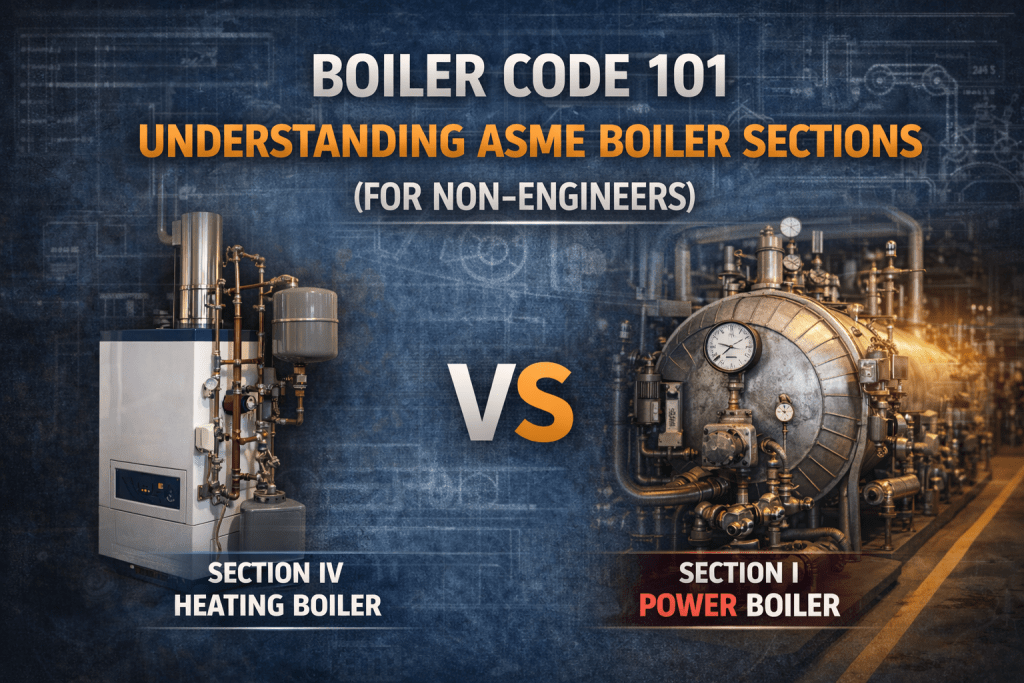

Pictured above: The Most Common ASME Boiler Sections

Boiler Code 101: Understanding ASME Boiler Sections (For Non-Engineers)

If you’ve ever nodded along in a meeting while someone casually says “That’s a Section I boiler”—you’re not alone.

ASME boiler codes can sound intimidating, especially if you’re not an engineer by trade. The good news? You don’t need to memorize the Code to understand the basics. You just need a clear map.

This Boiler Code 101 guide explains the major ASME boiler sections in plain English, what each one applies to, and why choosing the right section matters.

What Is ASME, and Why Does It Matter?

ASME stands for the American Society of Mechanical Engineers.

ASME publishes the Boiler and Pressure Vessel Code (BPVC)—a globally recognized set of rules that establishes minimum safety requirements for boilers and pressure equipment.

In short: – It keeps people safe – It standardizes design and construction – It gives inspectors and jurisdictions a common rulebook

If a boiler is built, installed, or inspected in the U.S. (and many places worldwide), ASME rules are usually involved.

What Does “Boiler Section” Mean?

The BPVC is divided into sections, each covering a different type of equipment or activity.

When someone says “Which section applies?”, they’re really asking:

What kind of boiler is this, and how severe are its operating conditions?

Different conditions = different rules.

The Most Common ASME Boiler Sections (Explained Simply) ASME Section I – Power Boilers

Think: industrial muscle.

Section I applies to power boilers that operate at: – Steam pressures above 15 psi, or – Hot water temperatures above 250°F

Typical uses: – Power generation – Industrial processes – Refineries and large manufacturing facilities

Why it’s strict: – High pressure and temperature mean high stored energy – Failures can be catastrophic

These boilers require: – Extensive inspection – Authorized Inspector involvement – ASME S-Stamp certification

ASME Section IV – Heating Boilers

Think: comfort and building heat.

Section IV applies to boilers used for: – Space heating – Domestic hot water

Operating limits: – Steam pressure 15 psi or less – Hot water temperature 250°F or less

Typical locations: – Schools – Hospitals – Office buildings – Apartments

These systems are still regulated—but with simpler rules because the risk level is lower.

ASME Section VIII – Pressure Vessels (Not Boilers)

This one causes a lot of confusion.

Section VIII applies to pressure vessels, not boilers.

Pressure vessels: – Store pressure – Do not generate steam for external use

Examples: – Air receivers – Separators – Accumulators

Even though they may look similar, boilers and pressure vessels follow very different rules.

Why Choosing the Right Section Matters

Selecting the wrong ASME section can lead to:

- Failed inspections

- Costly redesigns

- Project delays

- Equipment replacement

- Regulatory headaches

Inspectors and jurisdictions enforce capability, not intent.

If a boiler can exceed Section IV limits, it may be treated as Section I—even if you “never plan to run it that way.”

A Simple Way to Remember It

Ask three questions:

- Does it produce steam or hot water?

- What is the maximum pressure?

- What is the maximum temperature?

If either pressure or temperature crosses the Section IV limit, Section I usually applies.

Who Enforces These Rules?

ASME writes the Code—but enforcement comes from:

- Authorized Inspectors (AIs)

- Jurisdictional authorities

- Insurance and regulatory bodies

That’s why early code identification is so important—it affects everyone downstream.

Final Thoughts

You don’t need to be an engineer to understand boiler code fundamentals.

Knowing the difference between Section I, Section IV, and Section VIII helps you: – Ask better questions – Spot risks early – Avoid expensive surprises

Boiler code isn’t about red tape—it’s about managing energy safely.

And now? You’re officially fluent enough to keep up in the meeting.