ASME Section I vs Section IV: Key Differences Every Boiler Owner Should Know

Choosing the wrong ASME boiler code isn’t a small paperwork issue—it’s a project-stopping, inspection-failing, budget-burning problem.

This guide breaks it down clearly, practically, and without Code-induced headaches.

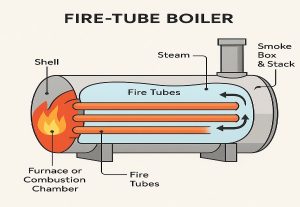

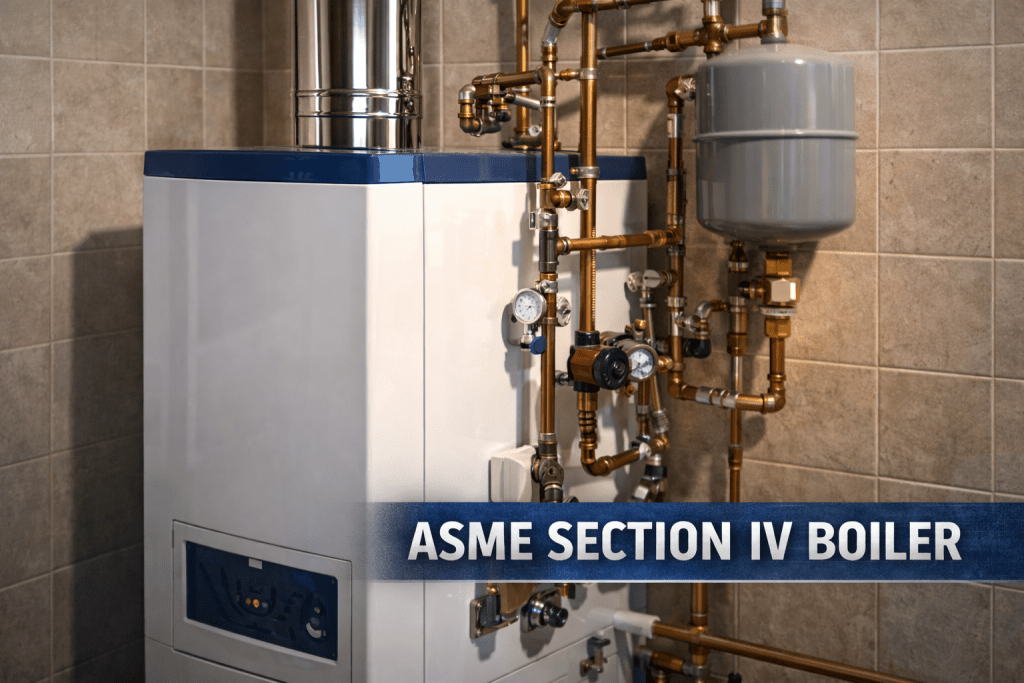

Pictured above:

Quick Overview: Section I vs. Section IV

Topic | ASME Section I | ASME Section IV |

Boiler Type | Power Boilers | Heating Boilers |

Steam Pressure | Above 15 psi | 15 psi or less |

Hot Water Temp | Above 250°F | 250°F or less |

Typical Use | Power generation & industrial processes | Building heat & hot water |

Code Stamp | S-Stamp | H-Stamp |

Risk Level | High | Moderate |

If your boiler crosses either the pressure or temperature threshold, Section I applies—no exceptions, no loopholes.

What Is ASME Section I?

ASME Section I governs power boilers operating at elevated pressures and temperatures where stored energy presents a significant hazard.

These boilers are commonly found in:

- Power plants

- Refineries

- Chemical and petrochemical facilities

- Pulp and paper mills

- Large industrial campuses

Section I emphasizes:

- Conservative design margins

- Strict material controls

- Qualified welding and procedures

- Mandatory Authorized Inspector involvement

- Formal certification and data reporting

This is the “no shortcuts allowed” side of boiler construction.

Pictured above: ASME Section I governs power boilers operating at elevated pressures and temperatures where stored energy presents a significant hazard.

What Is ASME Section IV?

ASME Section IV covers heating boilers used primarily for comfort heating and domestic hot water.

Typical installations include:

- Commercial buildings

- Schools and universities

- Hospitals

- Apartment complexes

- Small institutional facilities

Section IV still prioritizes safety, but:

- Design rules are less complex

- Pressures and temperatures are lower

- Fabrication requirements are reduced

- Inspection requirements are streamlined

It’s designed for systems where failure is serious—but not catastrophic.

Pictured above: ASME Section IV covers heating boilers used primarily for comfort heating and domestic hot water.

Why the Difference Matters (More Than You Think)

1. Inspection & Certification Requirements

Section I boilers:

- Require continuous involvement of an Authorized Inspector (AI)

- Must pass a witnessed hydrostatic test

- Require a Manufacturer’s Data Report

- Receive an ASME S-Stamp

Section IV boilers:

- Follow simplified inspection paths

- Receive an H-Stamp

- Often fall under lighter jurisdictional oversight

Selecting the wrong code can mean rebuilding equipment—or scrapping it entirely.

2. Design & Cost Implications

Section I boilers:

- Thicker materials

- Higher-grade alloys

- More conservative stress limits

- Extensive documentation

Section IV boilers:

- Lighter construction

- Lower material costs

- Faster fabrication timelines

Mistakenly designing a Section I boiler as Section IV can lead to major redesigns and six-figure surprises.

3. Jurisdictional Acceptance

Authorities Having Jurisdiction (AHJs) rely heavily on ASME code classification.

If your boiler:

- Exceeds 15 psi steam or 250°F water

- Supplies process steam (not just heat)

- Interfaces with turbines or industrial systems

…it will almost always be required to meet ASME Section I, regardless of how it was originally intended.

Common Misconceptions

- “It’s just for heating, so Section IV applies.” → Not always.

- “We’ll keep pressure low to avoid Section I.” → Temperature still matters.

- “The inspector will tell us later.” → That’s the expensive way to learn.

Early code determination is one of the smartest decisions in any boiler project.

How to Choose the Correct Code

Before design begins, ask:

- What is the maximum operating pressure?

- What is the maximum operating temperature?

- Is the steam used for process or power generation?

- What does the local jurisdiction require?

- Has an Authorized Inspector been consulted?

Answering these upfront avoids painful corrections downstream.

Final Thoughts

ASME Section I and Section IV serve different worlds—but confusing them can collapse a project fast.

Section I protects against high-energy failure. Section IV supports safe, efficient heating.

Knowing which side your boiler lives on isn’t just good engineering—it’s good risk management.