Browse Through Our Vessel Information Database

Dive into the world of pressure vessel description with collection of informative blogs. Explore the intricacies of design, manufacturing, and applications for a wide range of pressure vessels, from industrial boilers to high-pressure reactors.

- API Tanks (2)

- ASME (6)

- Boiler (15)

- Dehydration Unit (5)

- Fabrication (14)

- Heat Exchangers (22)

- Air-Cooled Heat Exchangers (5)

- Compact Heat Exchangers (4)

- Other Heat Exchangers (9)

- Shell and Tube Heat Exchangers (4)

- Piping (4)

- Production Drawings (1)

- Repair and Alteration (2)

- Separators (23)

- Gas Separator (4)

- Liquid Separators (1)

- Magnetic Separators (1)

- Sand Separators (6)

- Three Phase Separators (7)

- Two Phase Separators (5)

- Stamps (15)

- H Stamp (2)

- Joint Review (2)

- PP Stamp (1)

- S Stamp (7)

- U Stamp (7)

- U2 Stamp (2)

- UM Stamp (2)

- Training Videos (1)

- Vessel Knowledge (90)

- See All Articles

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

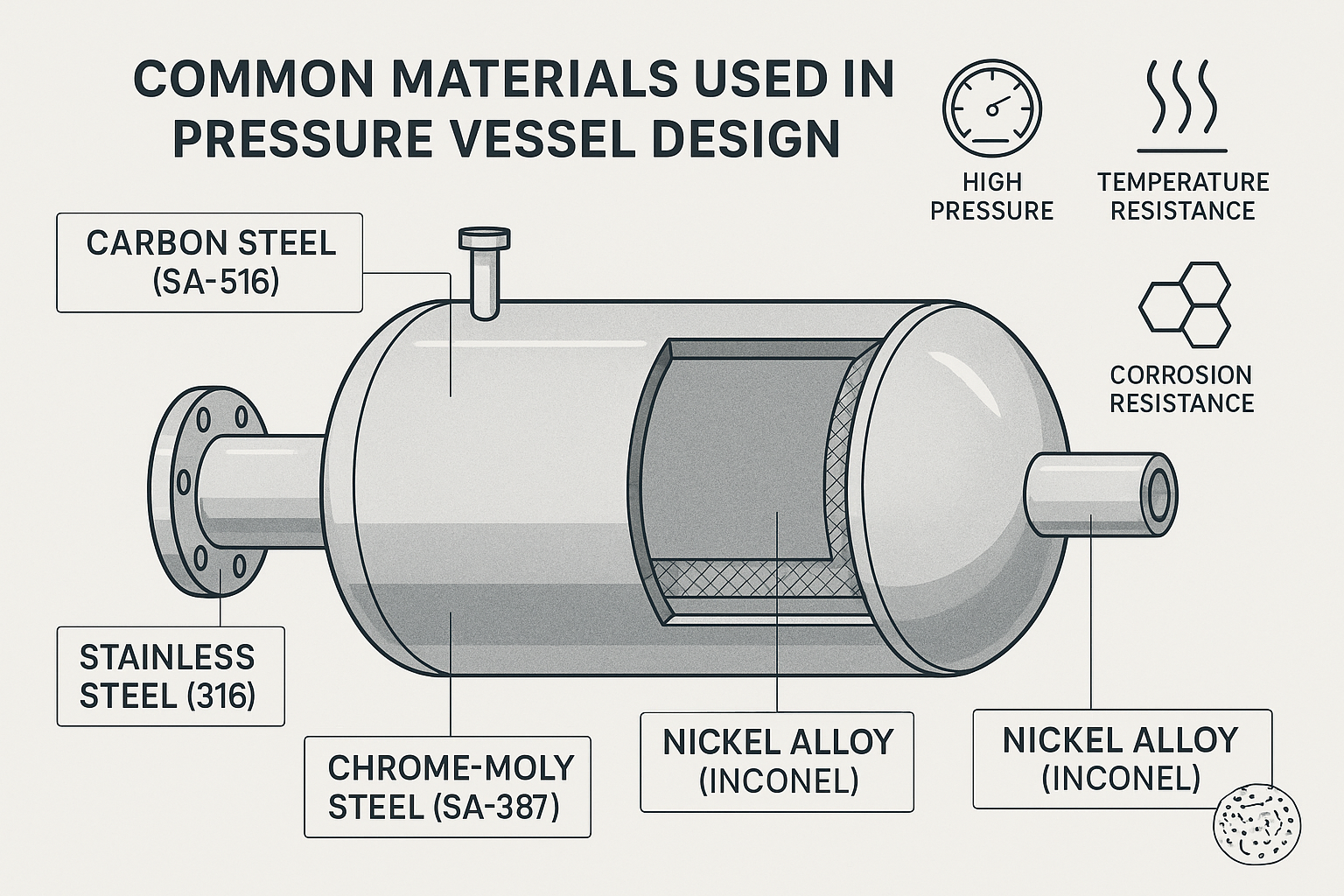

When it comes to designing pressure vessels, one of the most critical decisions engineers face is selecting the right material. In high-pressure environments, the wrong choice can lead to catastrophic failure, regulatory violations, or costly downtime. The right material, on the other hand, ensures...

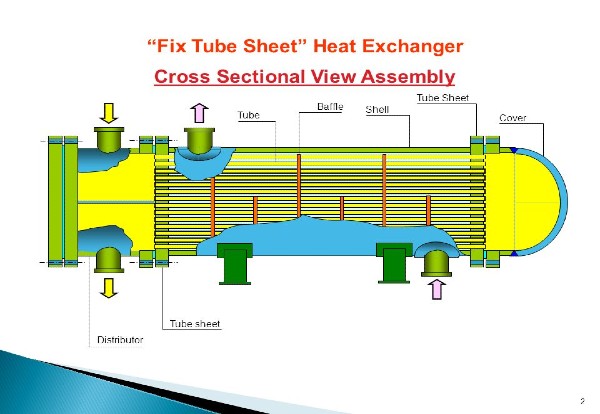

In a fixed tube sheet heat exchanger, one fluid flows through the tubes, while the other fluid flows through the shell. Heat is transferred between the two fluids through the tube walls. The tube sheets are securely fastened to the shell, providing a rigid...

An S-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It signifies that a manufacturer is authorized to build and stamp power boilers, which are pressure vessels designed to generate steam for various applications, such as...

Sand separators are crucial components in various industries, including oil and gas, water treatment, and manufacturing. They are designed to remove solid particles, such as sand, dirt, and scale, from liquid streams. The choice of sand separator depends on various factors, including the type...

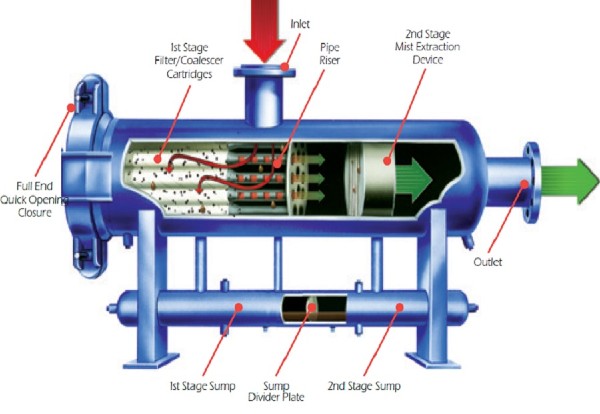

Filter separators are widely used in various industries to remove solid particles from liquid streams. They are essential for maintaining product quality, protecting downstream equipment, and ensuring efficient processes.

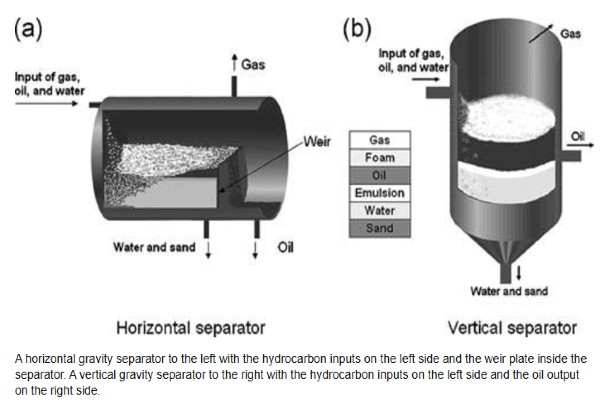

Gravity separators are a fundamental type of separation equipment that leverages the principle of density difference to separate solid particles from liquids or different liquid phases from each other. They are widely used in various industries, including oil and gas, water treatment, and mining.

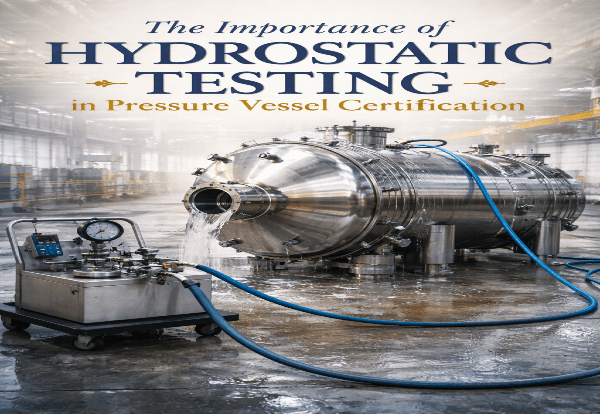

Before a pressure vessel ever goes into service, it must prove its integrity. One of the most critical steps in this process is hydrostatic testing—a time-tested method for ensuring that a vessel can safely handle its intended pressure load.

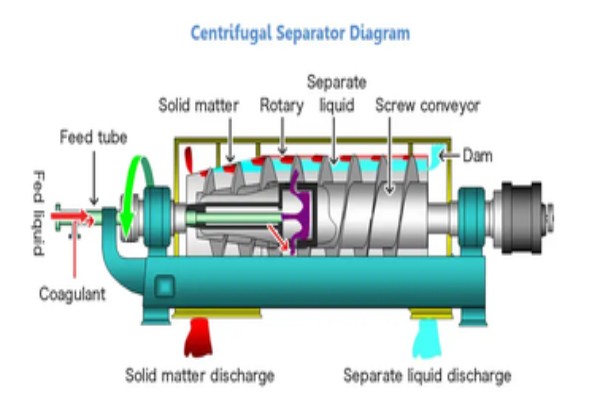

A centrifugal separator typically consists of a rotating bowl or drum. The fluid mixture is introduced into the bowl, and as the bowl spins, the centrifugal force causes the denser particles to move towards the outer wall, while the lighter fluid remains near the...

Glycol dehydrators, also known as gas dehydrators or TEG units, are used to remove water vapor from natural gas. The process of dehydration is important for two reasons.

If the S-Stamp is the finish line, the Authorized Inspector (AI) is the gatekeeper holding the stopwatch. Before that stamp ever touches a boiler, inspectors are verifying far more than weld quality or paperwork completeness. They’re answering one critical question:

Browse Through Our Vessel Information Database Below

Dive into the world of pressure vessel description with collection of informative blogs. Explore the intricacies of design, manufacturing, and applications for a wide range of pressure vessels, from industrial boilers to high-pressure reactors. Gain valuable insights into safety regulations, maintenance best practices, and the latest advancements in pressure vessel technology. Whether you’re an industry professional, a student, or simply curious about these critical components, our blog section offers a wealth of knowledge and resources.

Our Blog Site is still in progress. Keep checking back for more!

- See All Articles

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

The ASME® BPVC specifies a range of materials that are suitable for use in pressure vessels and boilers. These materials are often listed in the ASME® Boiler and Pressure Vessel Code, Section II, Part A, and other relevant standards

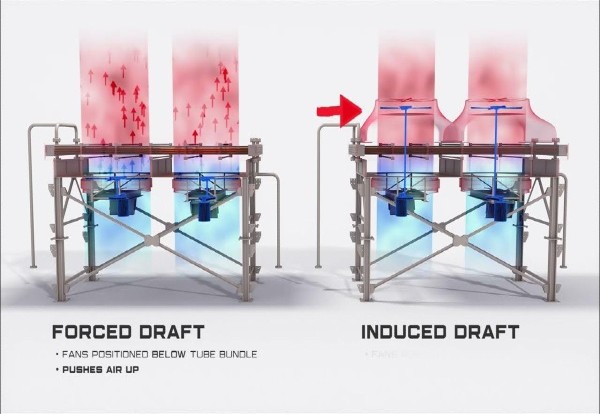

Induced draft air coolers are a type of air-cooled heat exchanger that uses fans to draw air across the finned tubes. This design offers several advantages over forced draft air coolers, including quieter operation and lower energy consumption. In an induced draft air cooler,...

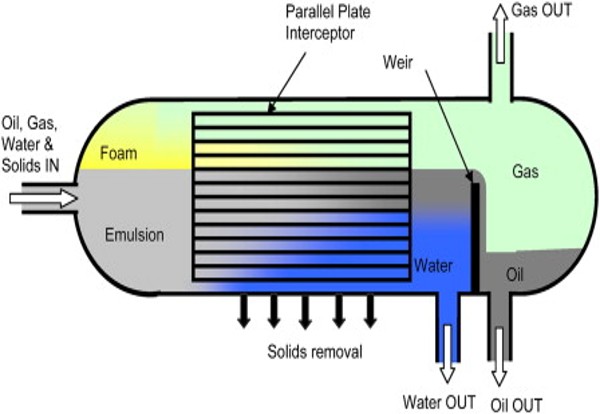

In a horizontal three-phase separator with an overflow weir, fluid enters the vessel through an inlet and immediately hits an inlet diverter. The sudden impact and change of direction helps to release the gas by breaking the surface tension of the liquid.

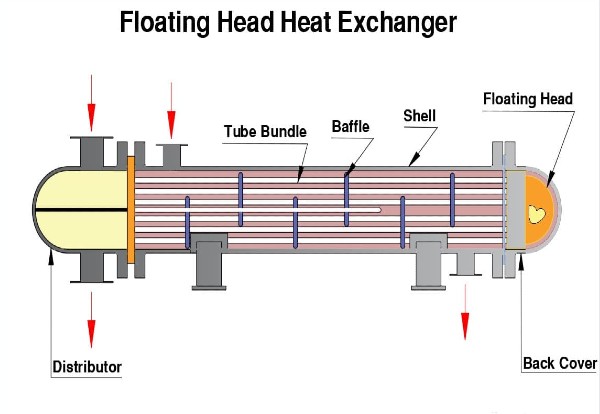

Floating head heat exchangers are a type of shell and tube heat exchanger designed to accommodate thermal expansion and contraction of the tube bundle. This design is particularly useful for high-pressure applications where significant temperature differences can occur between the shell-side and tube-side fluids.

A forced draft air cooler typically consists of a bundle of finned tubes arranged in a specific configuration. The process fluid flows through the tubes, while air is forced across the fins by fans. The heat from the process fluid is transferred to the...

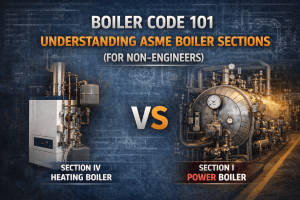

ASME boiler codes can sound intimidating, especially if you’re not an engineer by trade. The good news? You don’t need to memorize the Code to understand the basics. You just need a clear map.

In this must-watch episode, we break down the major updates in the 2025 edition of the ASME Boiler and Pressure Vessel Code (BPVC), released on July 1, 2025, and mandatory starting January 1, 2026. Whether you're a manufacturer, purchaser, designer, inspector, or anyone working...

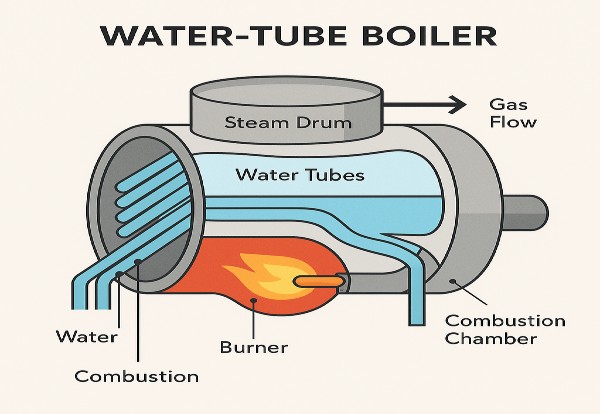

A water-tube boiler is a type of boiler where water circulates inside the tubes, and hot combustion gases flow around the outside of those tubes. This design is ideal for high-pressure applications and large steam outputs, making it the go-to choice for power plants,...

Air-cooled heat exchangers typically consist of a bundle of tubes through which the process fluid flows. Fins are attached to the tubes to increase the surface area for heat transfer. Air is forced or drawn across the finned tubes, removing heat from the process...

An API storage tank is a large, welded storage tank designed and constructed in accordance with standards developed by the American Petroleum Institute (API).