Browse Through Our Vessel Information Database

Dive into the world of pressure vessel description with collection of informative blogs. Explore the intricacies of design, manufacturing, and applications for a wide range of pressure vessels, from industrial boilers to high-pressure reactors.

- API Tanks (2)

- ASME (6)

- Boiler (15)

- Dehydration Unit (5)

- Fabrication (14)

- Heat Exchangers (22)

- Air-Cooled Heat Exchangers (5)

- Compact Heat Exchangers (4)

- Other Heat Exchangers (9)

- Shell and Tube Heat Exchangers (4)

- Piping (4)

- Production Drawings (1)

- Repair and Alteration (2)

- Separators (23)

- Gas Separator (4)

- Liquid Separators (1)

- Magnetic Separators (1)

- Sand Separators (6)

- Three Phase Separators (7)

- Two Phase Separators (5)

- Stamps (15)

- H Stamp (2)

- Joint Review (2)

- PP Stamp (1)

- S Stamp (7)

- U Stamp (7)

- U2 Stamp (2)

- UM Stamp (2)

- Training Videos (1)

- Vessel Knowledge (90)

- See All Articles

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

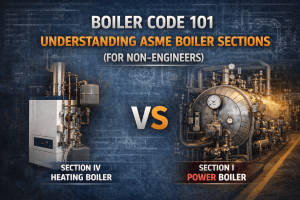

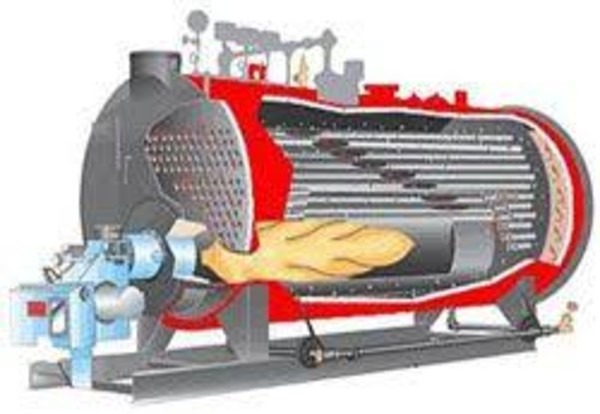

Industrial boilers are the beating heart of countless facilities—from chemical plants and refineries to food processing and textile mills. But not all boilers are created equal.

Air-cooled heat exchangers typically consist of a bundle of tubes through which the process fluid flows. Fins are attached to the tubes to increase the surface area for heat transfer. Air is forced or drawn across the finned tubes, removing heat from the process...

Glycol dehydrators, also known as gas dehydrators or TEG units, are used to remove water vapor from natural gas. The process of dehydration is important for two reasons.

An API storage tank is a large, welded storage tank designed and constructed in accordance with standards developed by the American Petroleum Institute (API).

This article highlights the most common ASME Section I mistakes that trigger inspection red flags, why inspectors care about them, and how to avoid unnecessary pain at the worst possible time.

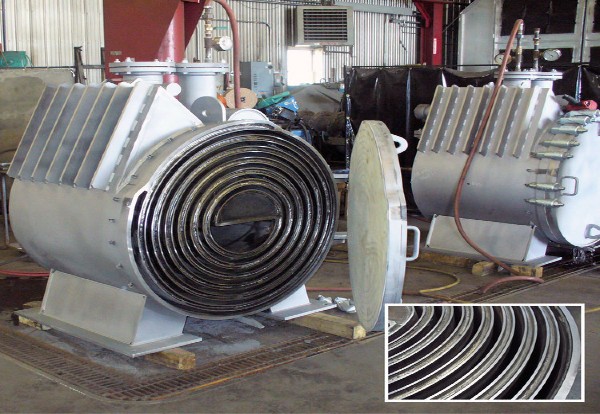

A spiral heat exchanger consists of two spiral-wound channels, one for each fluid. The two channels are separated by a partition, and the fluids flow in opposite directions through the channels. This counter-current flow arrangement maximizes heat transfer efficiency. Spiral heat exchangers are a...

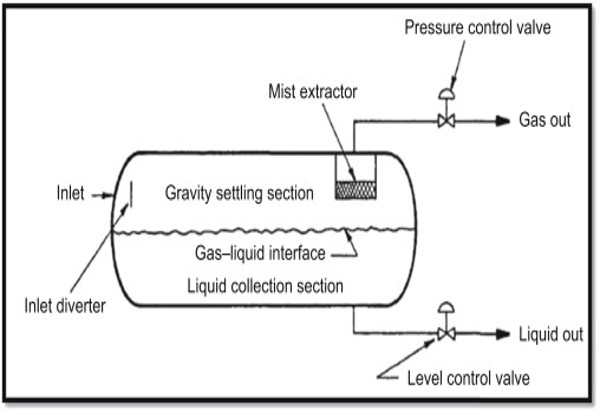

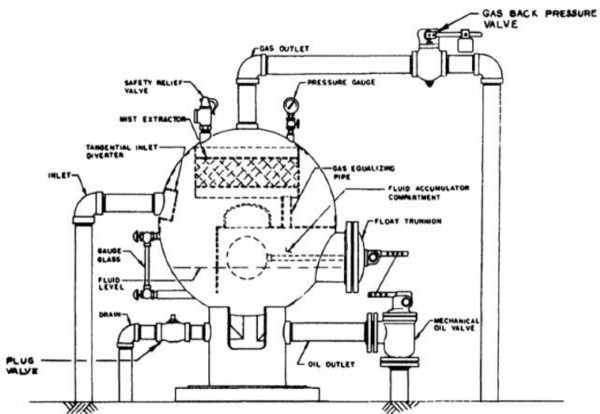

Horizontal separators are ideally suited to wellstreams having high gas-oil ratios, constant flow, and small liquid surge characteristics. Horizontal separators are smaller and less expensive than vertical separators for a given gas capacity. Liquid particles in the wellstream travel horizontally and downward at the...

Steam-heat exchangers are used to raise the temperature of well effluents to prevent hydrate formation, reduce viscosity, and break down emulsions for efficient separation of oil and water. Because steam-heat exchangers drastically reduce risk, they are used on offshore platforms and in other work...

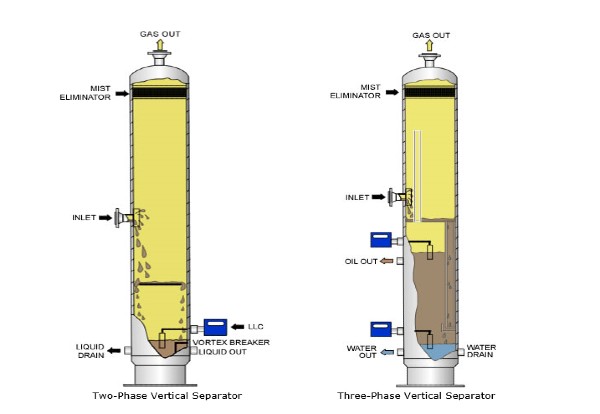

A three-phase separator is a crucial piece of equipment in the oil and gas industry, designed to separate a mixture of oil, gas, and water into its individual components. The vertical three-phase separator, equipped with interface control, is a particularly efficient design for maintaining...

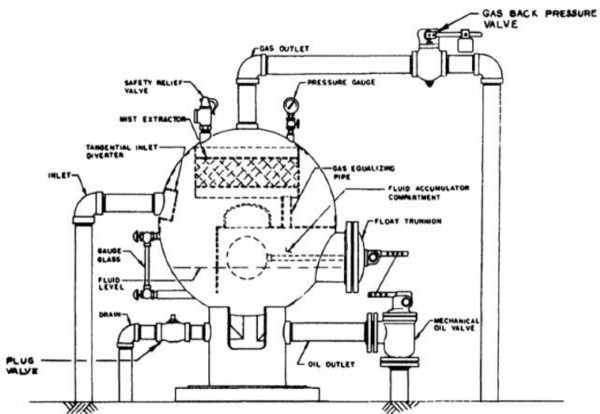

Two-Phase Spherical Separators operate on the principle of gravity separation. When a gas-liquid mixture enters the vessel, the heavier liquid phase settles to the bottom, while the lighter gas phase rises to the top. The unique spherical shape of the vessel promotes efficient separation...

A U-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It signifies that a pressure vessel has been manufactured and inspected in accordance with the rigorous standards outlined in the ASME® Boiler and Pressure Vessel Code...

The key difference between a two-phase separator and a three-phase separator is the number of phases they are designed to separate. While a two-phase separator separates gas and liquid, a three-phase separator can handle gas, oil, and water. The design and internal components of...

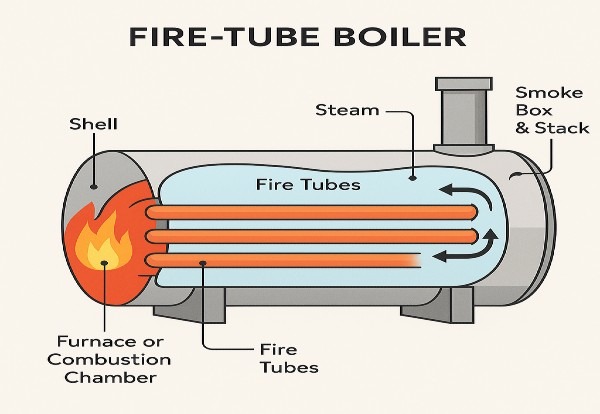

A fire-tube boiler is a type of boiler where hot gases pass through tubes, which are surrounded by water. It's one of the most common boiler types used in low- to medium-pressure steam applications — especially in heating systems, commercial buildings, and smaller industrial...

In industrial operations, boiler downtime isn’t just an inconvenience—it’s a profit killer. Whether it’s lost production, emergency repair costs, or compliance penalties, a boiler failure can have far-reaching impacts. Fortunately, many of these issues are preventable with a strong, proactive maintenance strategy. In this...

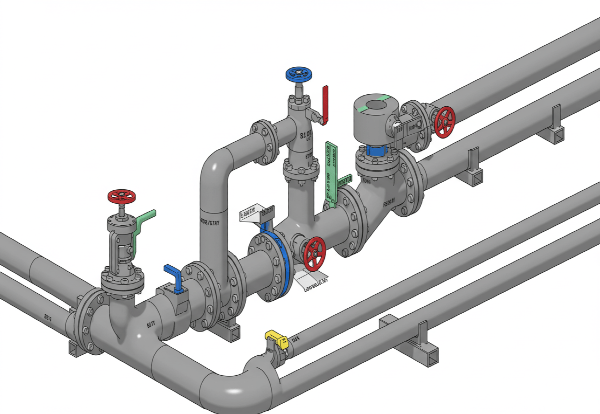

Stress analysis is a critical aspect of B31.1 piping design, ensuring that the piping system can withstand the various loads and pressures it will experience during operation.

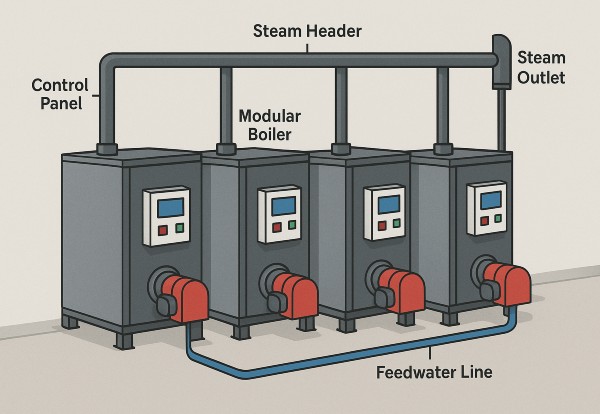

Modular boilers are compact, factory-assembled boiler units designed to work together in a series — offering scalable steam or hot water generation based on demand. Rather than relying on a single large boiler, modular systems operate with multiple small units that can be staged...

ASME® BPVC Section II, Part A is a critical reference document for engineers and designers involved in the construction of pressure vessels and boilers. It provides a comprehensive list of ferrous materials suitable for use in these applications.

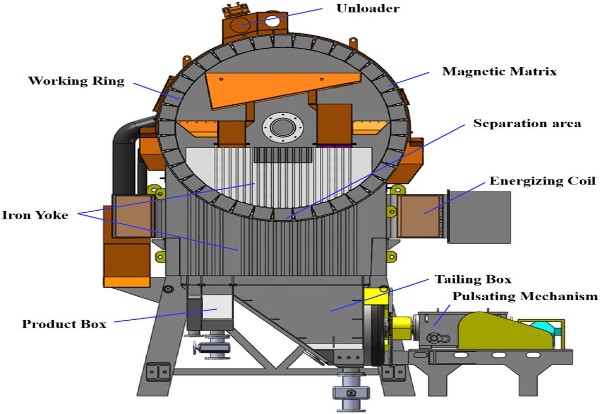

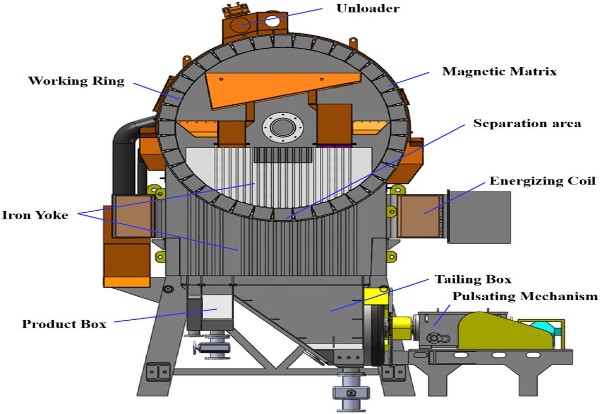

Magnetic separators utilize magnetic forces to separate magnetic materials from non-magnetic materials. They are widely used in various industries, including mining, recycling, and food processing. Magnetic separators are a valuable tool for separating materials based on their magnetic properties. By understanding the principles of...

Applicants for new issuance or renewal of an ASME® Certificate(s) of Authorization should be aware that the Joint Review will require implementation and demonstration of their Quality Control Program. The purpose of the demonstration is to have the Applicant provide evidence of their knowledge...

Go into your Joint Review with confidence. Use our Pre-Joint Review checklist to help determine if you have what you need or just get you on the track.

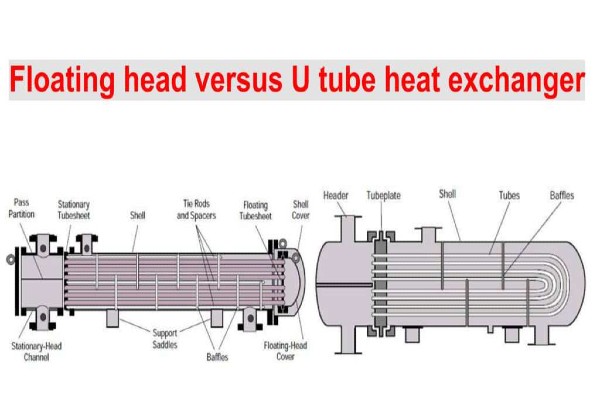

Shell and tube heat exchangers are a common type of heat exchanger used in various industries. Within this category, two primary designs stand out: floating head and U-tube. Each design has its own advantages and disadvantages, making it suitable for specific applications.

Browse Through Our Vessel Information Database Below

Dive into the world of pressure vessel description with collection of informative blogs. Explore the intricacies of design, manufacturing, and applications for a wide range of pressure vessels, from industrial boilers to high-pressure reactors. Gain valuable insights into safety regulations, maintenance best practices, and the latest advancements in pressure vessel technology. Whether you’re an industry professional, a student, or simply curious about these critical components, our blog section offers a wealth of knowledge and resources.

Our Blog Site is still in progress. Keep checking back for more!

- See All Articles

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

A U2-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It authorizes a manufacturer to repair and alter existing pressure vessels and boilers. This certification ensures that repairs and alterations are performed in accordance with the...

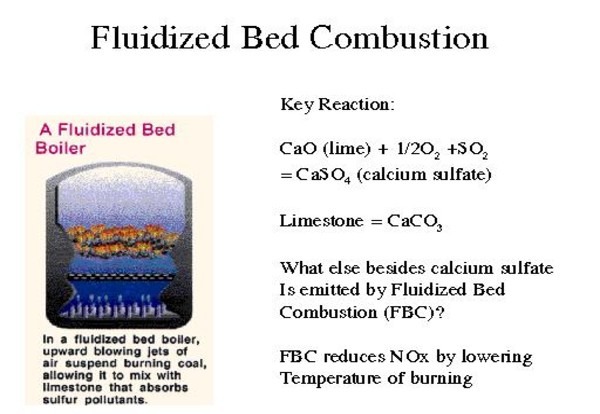

Fluidized bed boilers (FBBs) use a unique combustion method where solid fuel particles are suspended in an upward flow of air — creating a fluid-like state. This allows for highly efficient combustion at lower temperatures with improved emissions control.

Go into your Joint Review with confidence. Use our Pre-Joint Review checklist to help determine if you have what you need or just get you on the track.

Steam Heat Exchanger - Indirect Heater is used to heat the well effluent after it flows out of the well and prior to the separating process. This type of heat exchanger is also called a direct heating furnace which allows it to heat up...

Steam-heat exchangers are used to raise the temperature of well effluents to prevent hydrate formation, reduce viscosity, and break down emulsions for efficient separation of oil and water. Because steam-heat exchangers drastically reduce risk, they are used on offshore platforms and in other work...

Obtaining a U-Stamp or U2-Stamp from the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI) is a significant achievement for manufacturers and fabricators of pressure vessels and boilers. These certifications signify adherence to rigorous quality, safety, and performance standards.

The difference between the U designation and the UM designation is related to size. However, this is not the only difference between the two. UM designated pressure vessels are not required to undergo the same inspection regimen as the larger, U stamped pressure vessels.

Glycol dehydrators, also known as gas dehydrators or TEG units, are used to remove water vapor from natural gas. The process of dehydration is important for two reasons.

The selection of appropriate materials is a critical aspect of B31.1 piping design. The choice of material depends on factors such as temperature, pressure, corrosion resistance, and cost. By carefully selecting materials and considering the factors discussed above, engineers can design piping systems that...

Two-Phase Spherical Separators operate on the principle of gravity separation. When a gas-liquid mixture enters the vessel, the heavier liquid phase settles to the bottom, while the lighter gas phase rises to the top. The unique spherical shape of the vessel promotes efficient separation...

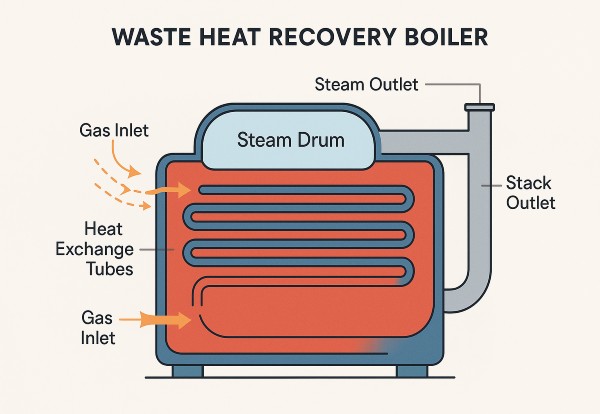

Waste heat recovery boilers (WHRBs) capture hot exhaust gases from industrial processes or engines and use that heat to generate steam or hot water — without burning additional fuel.

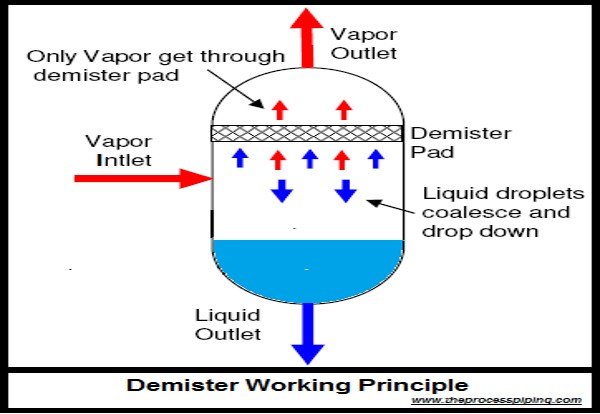

A demister is also known as a demister pad, mist pad, wire mesh demister, mesh mist eliminator, catching mist, and mist eliminator. It is a device often fitted to vapor–liquid separator vessels to enhance the removal of liquid droplets entrained in a vapor stream.

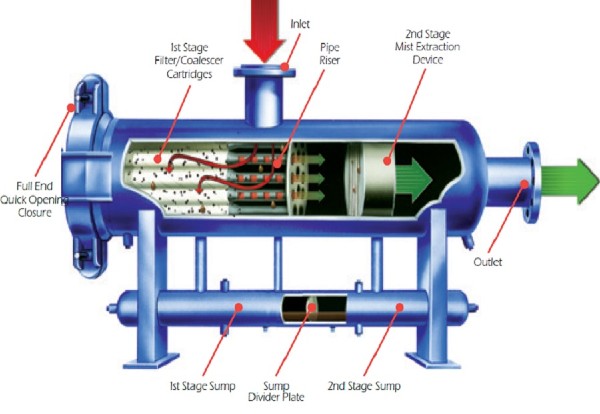

Filter separators are widely used in various industries to remove solid particles from liquid streams. They are essential for maintaining product quality, protecting downstream equipment, and ensuring efficient processes.

Industrial boilers are the beating heart of countless facilities—from chemical plants and refineries to food processing and textile mills. But not all boilers are created equal.

The ASME® B31.1 Code for Power Piping is a widely recognized standard that provides guidelines for the design, fabrication, and installation of piping systems for power plants. This code ensures the safety and reliability of piping systems by establishing rigorous design and construction standards.

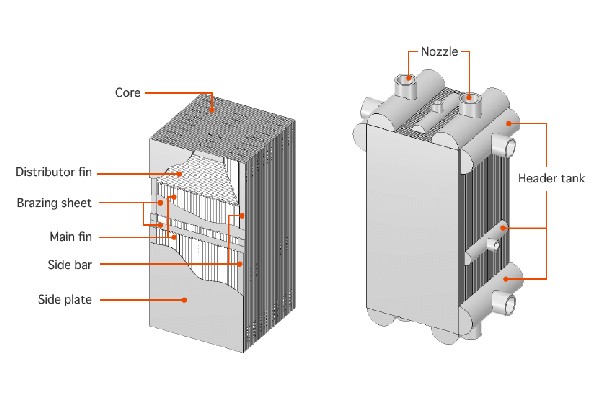

A plate fin heat exchanger consists of a core, which is a stack of corrugated plates, and fins, which are attached to the plates to increase the surface area for heat transfer. One fluid flows through the channels formed by the plates, while the...

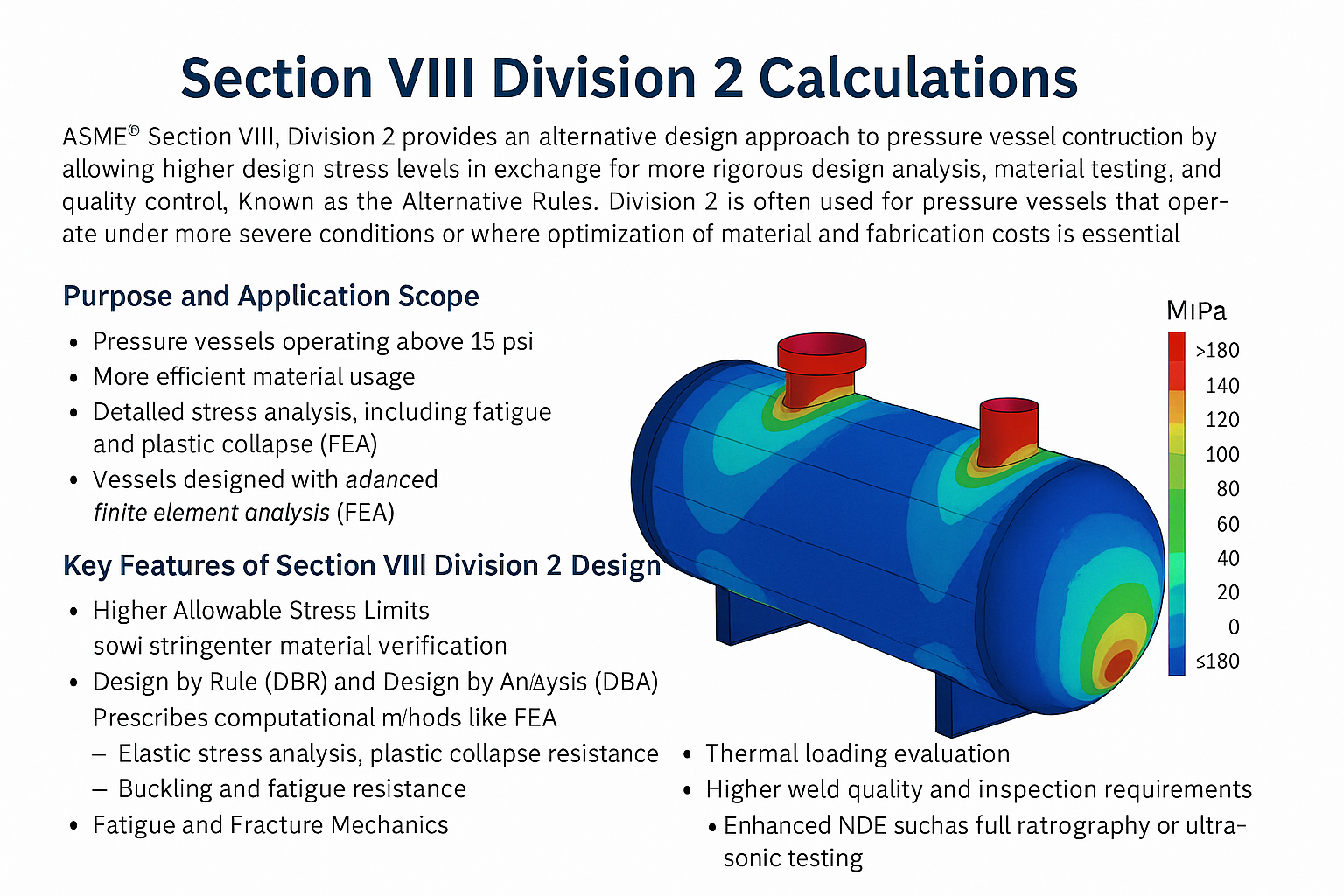

ASME® Section VIII, Division 2 provides an alternative design approach to pressure vessel construction by allowing higher design stress levels in exchange for more rigorous design analysis, material testing, and quality control.

Radiographic Testing (RT) is a powerful NDE technique widely used in the manufacturing of pressure vessels and boilers. It involves the use of ionizing radiation to penetrate the material and create an image of internal features.

Non-Destructive Examination (NDE) is a crucial aspect of the manufacturing process for pressure vessels and boilers. It involves a variety of techniques to detect flaws and defects without damaging the material. For U-Stamp certified products, NDE is essential to ensure the integrity and safety...

Magnetic separators utilize magnetic forces to separate magnetic materials from non-magnetic materials. They are widely used in various industries, including mining, recycling, and food processing. Magnetic separators are a valuable tool for separating materials based on their magnetic properties. By understanding the principles of...

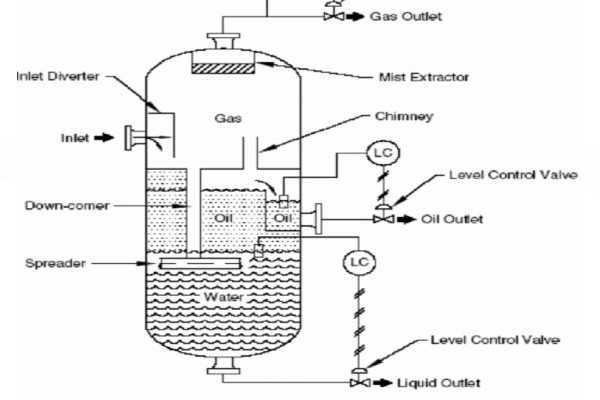

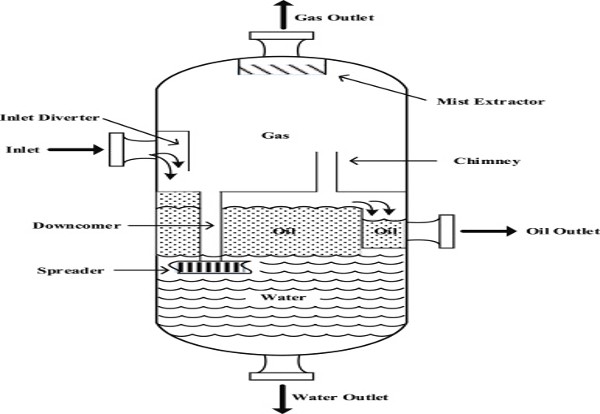

A three-phase separator is a crucial piece of equipment in the oil and gas industry, designed to separate a mixture of oil, gas, and water into its individual components. The vertical three-phase separator, equipped with a downcomer and spreader, is a particularly efficient design...