Browse Through Our Vessel Information Database

Dive into the world of pressure vessel description with collection of informative blogs. Explore the intricacies of design, manufacturing, and applications for a wide range of pressure vessels, from industrial boilers to high-pressure reactors.

- API Tanks (2)

- ASME (6)

- Boiler (15)

- Dehydration Unit (5)

- Fabrication (14)

- Heat Exchangers (22)

- Air-Cooled Heat Exchangers (5)

- Compact Heat Exchangers (4)

- Other Heat Exchangers (9)

- Shell and Tube Heat Exchangers (4)

- Piping (4)

- Production Drawings (1)

- Repair and Alteration (2)

- Separators (23)

- Gas Separator (4)

- Liquid Separators (1)

- Magnetic Separators (1)

- Sand Separators (6)

- Three Phase Separators (7)

- Two Phase Separators (5)

- Stamps (15)

- H Stamp (2)

- Joint Review (2)

- PP Stamp (1)

- S Stamp (7)

- U Stamp (7)

- U2 Stamp (2)

- UM Stamp (2)

- Training Videos (1)

- Vessel Knowledge (90)

- See All Articles

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

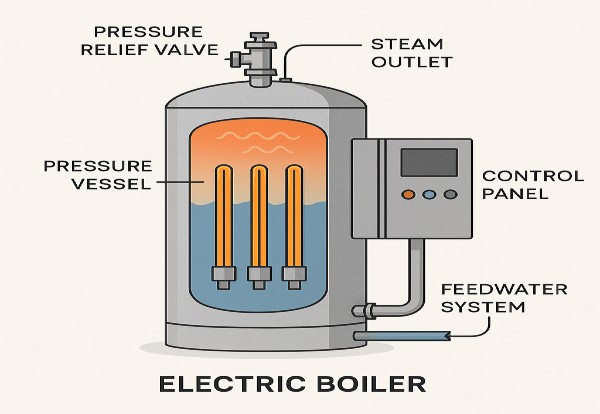

Electric boilers use electricity to generate steam or hot water — eliminating the need for fuel combustion. Unlike traditional boilers, there are no burners, gas valves, or flue stacks. Heat is generated through electrical resistance or electrode-type elements, making them clean, quiet, and often...

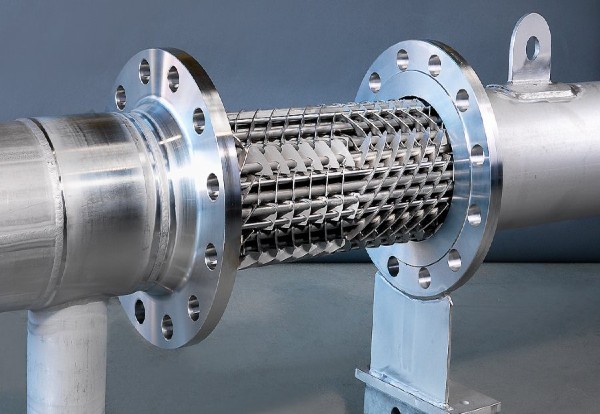

Compact heat exchangers are a type of heat exchanger designed to provide a high heat transfer rate in a small footprint. They are commonly used in applications where space is limited, such as in aerospace, automotive, and electronics industries.

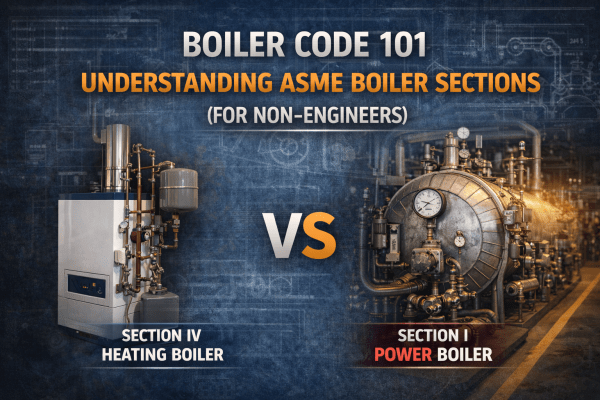

ASME Section I of the Boiler and Pressure Vessel Code (BPVC) governs the design, construction, and certification of power boilers—the heavy hitters used to generate steam or high‑temperature water for power generation, industrial processes, and large facilities. This section exists for one reason above...

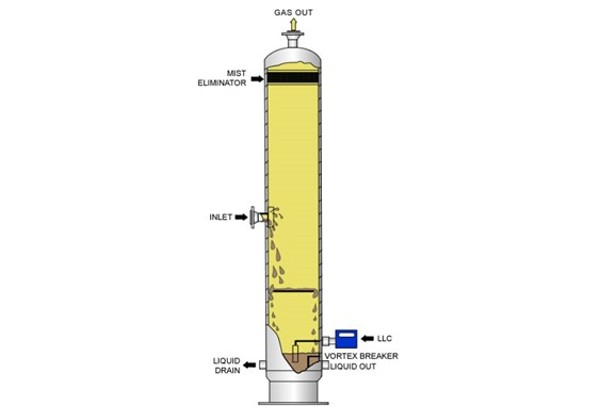

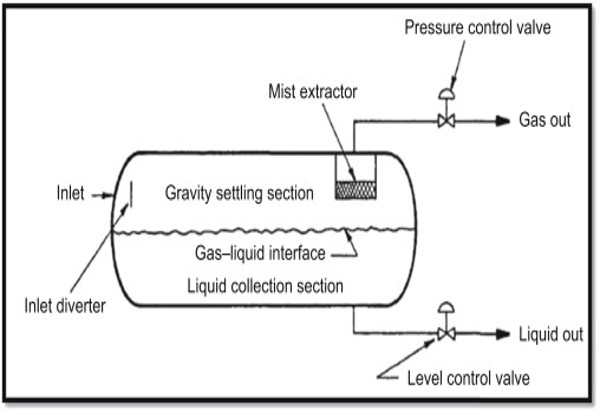

Depending on the specific application and the vapor-liquid mixture being separated, two-phase vessels can be oriented vertically or horizontally. In their simplest form, they are an empty tank that are used to reduce the velocity of a fluid on entry, thus allowing the liquid...

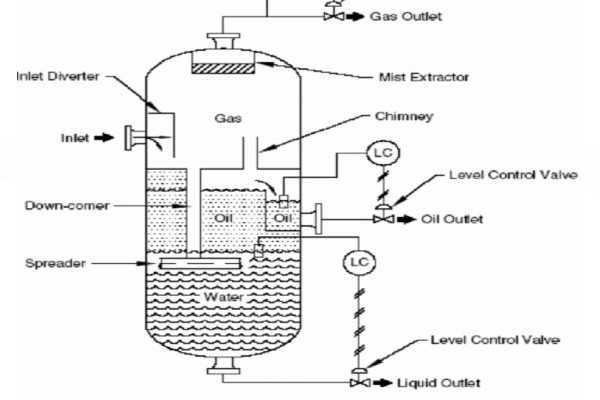

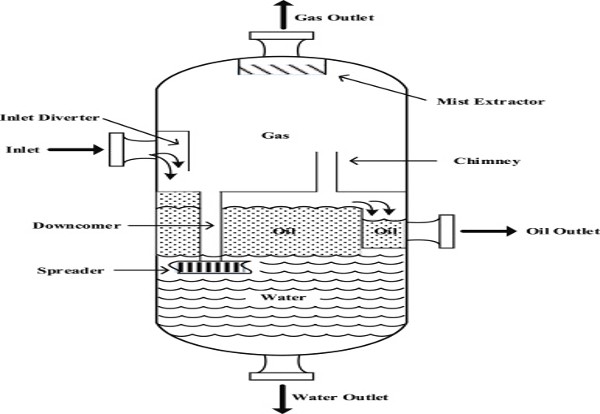

A three-phase separator is a crucial piece of equipment in the oil and gas industry, designed to separate a mixture of oil, gas, and water into its individual components. The vertical three-phase separator, equipped with interface control, is a particularly efficient design for maintaining...

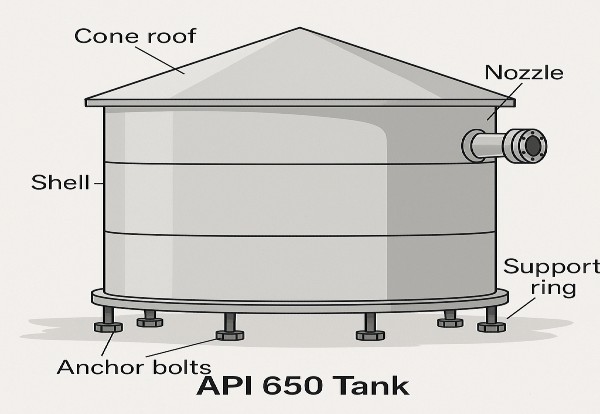

API 650 is the industry standard for the design and construction of large, field-erected storage tanks that operate at atmospheric pressure or low internal pressures (not exceeding 2.5 psig). These tanks are essential for safely storing crude oil, petroleum products, water, chemicals, and other...

Mix exchangers are a type of heat exchanger that combines two or more fluid streams to achieve a desired temperature or composition. They are widely used in various industries, including chemical processing, petroleum refining, and power generation. Mix exchangers play a critical role in...

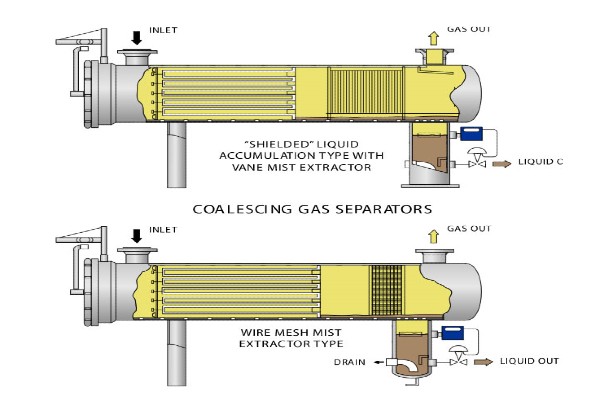

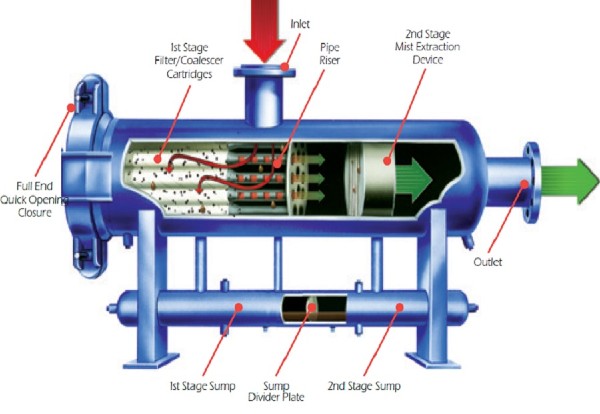

Coalescing gas separators are designed specifically for the removal of mist, fog, and dust from gas streams. These contaminants usually exist with the bulk of the particles having diameters considerably less than 10 microns; therefore, standard separators or scrubbers are not capable of effectively...

Glycol dehydration processes utilize glycol solvents to remove water from wet natural gas to meet pipeline quality specifications or condition the gas for condensate liquids removal.

Plate and frame heat exchangers are a type of heat exchanger that uses a series of corrugated plates to transfer heat between two fluids. The plates are stacked together, forming narrow channels through which the fluids flow. This design allows for a large heat...

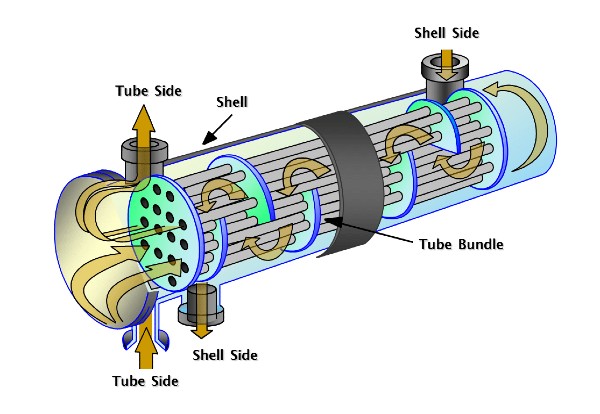

Shell and tube heat exchangers are one of the most common types of heat exchangers used in various industries, including oil and gas, chemical processing, power generation, and HVAC systems. They are versatile and reliable, capable of handling a wide range of fluids and...

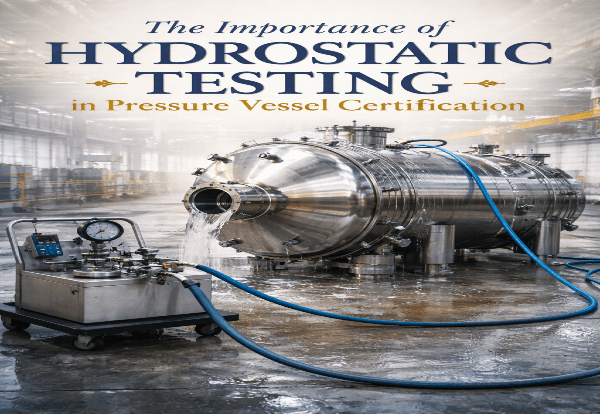

Before a pressure vessel ever goes into service, it must prove its integrity. One of the most critical steps in this process is hydrostatic testing—a time-tested method for ensuring that a vessel can safely handle its intended pressure load.

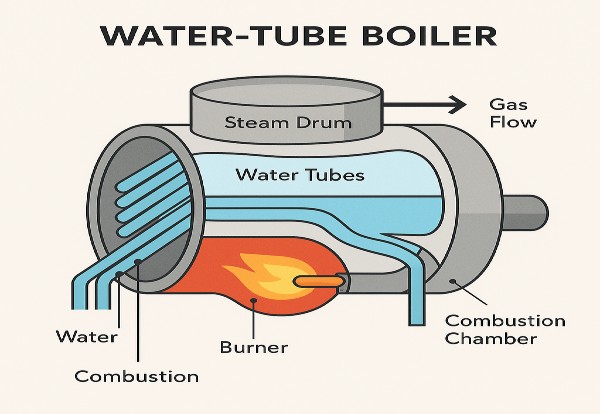

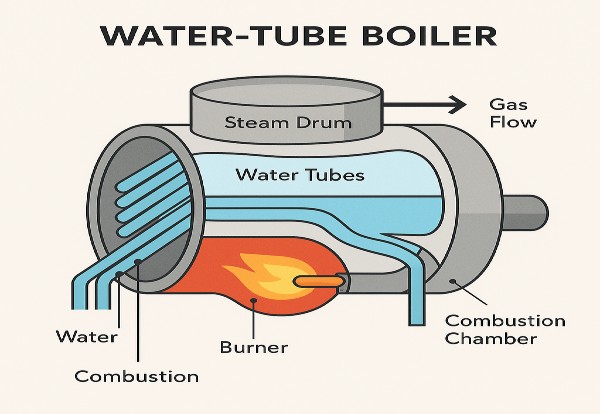

A water-tube boiler is a type of boiler where water circulates inside the tubes, and hot combustion gases flow around the outside of those tubes. This design is ideal for high-pressure applications and large steam outputs, making it the go-to choice for power plants,...

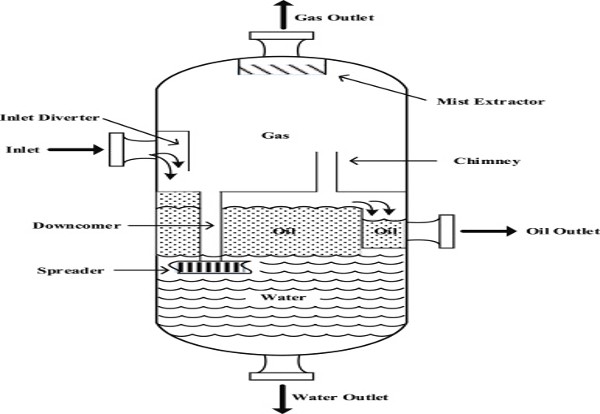

A three-phase separator is a crucial piece of equipment in the oil and gas industry, designed to separate a mixture of oil, gas, and water into its individual components. The vertical three-phase separator, equipped with a downcomer and spreader, is a particularly efficient design...

Applicants for new issuance or renewal of an ASME® Certificate(s) of Authorization should be aware that the Joint Review will require implementation and demonstration of their Quality Control Program. The purpose of the demonstration is to have the Applicant provide evidence of their knowledge...

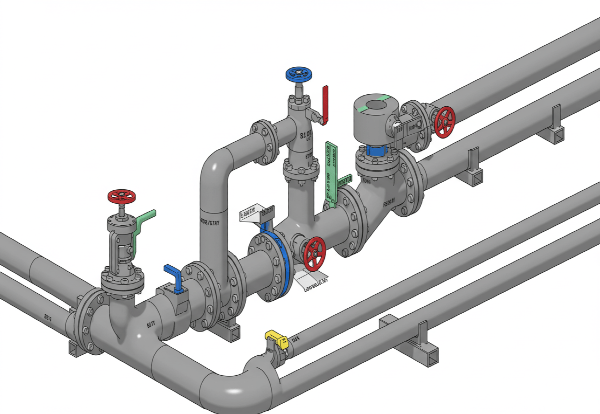

Welding is a critical aspect of B31.1 piping design and construction. The ASME® B31.1 Code provides specific requirements for welding procedures to ensure the quality and integrity of piping systems.

In this must-watch episode, we break down the major updates in the 2025 edition of the ASME Boiler and Pressure Vessel Code (BPVC), released on July 1, 2025, and mandatory starting January 1, 2026. Whether you're a manufacturer, purchaser, designer, inspector, or anyone working...

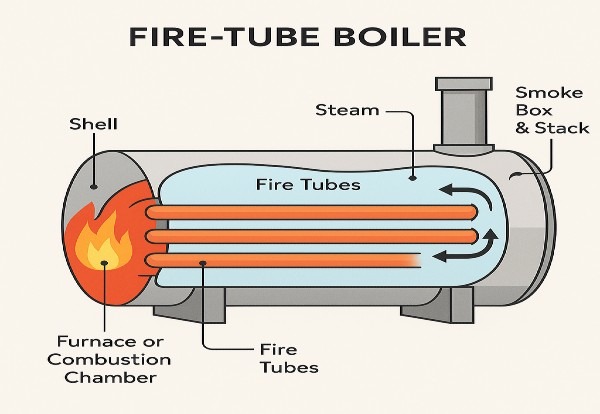

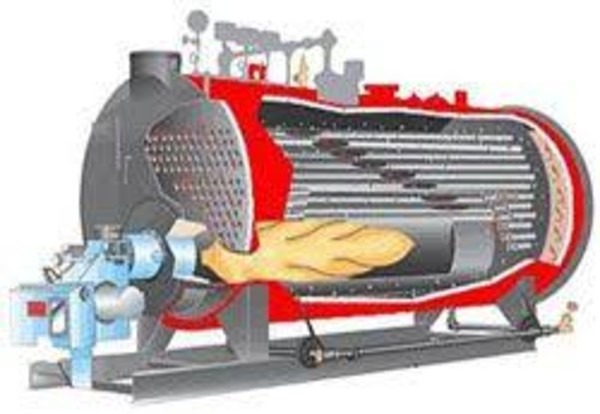

A fire-tube boiler is a type of boiler where hot gases pass through tubes, which are surrounded by water. It's one of the most common boiler types used in low- to medium-pressure steam applications — especially in heating systems, commercial buildings, and smaller industrial...

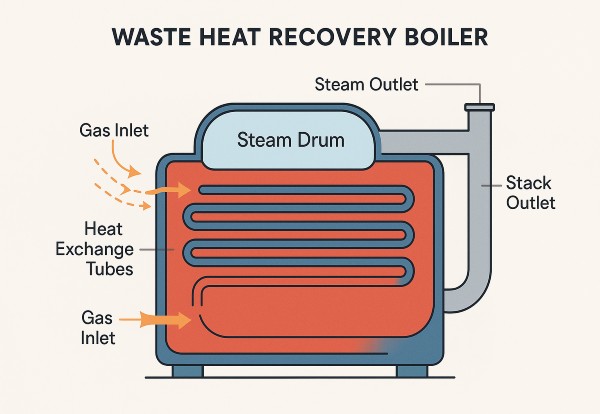

Waste heat recovery boilers (WHRBs) capture hot exhaust gases from industrial processes or engines and use that heat to generate steam or hot water — without burning additional fuel.

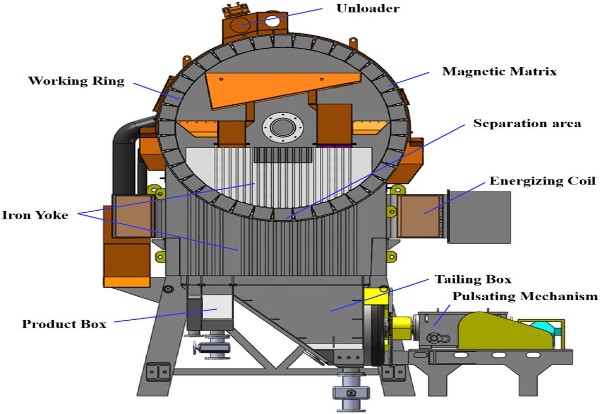

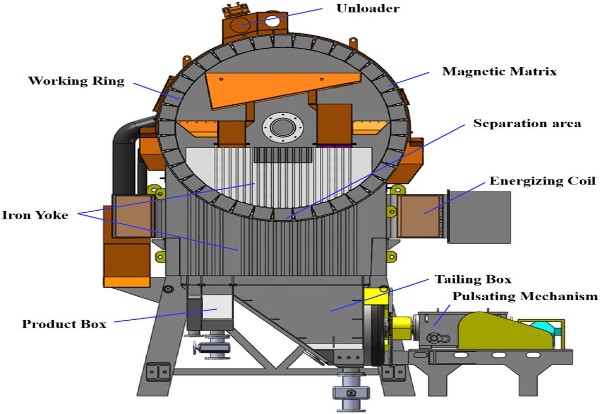

Magnetic separators utilize magnetic forces to separate magnetic materials from non-magnetic materials. They are widely used in various industries, including mining, recycling, and food processing. Magnetic separators are a valuable tool for separating materials based on their magnetic properties. By understanding the principles of...

Microchannel heat exchangers are a type of heat exchanger with channels that have characteristic dimensions in the micrometer range. These tiny channels offer significant advantages in terms of heat transfer efficiency and compact design. In a microchannel heat exchanger, the two fluids flow through...

Browse Through Our Vessel Information Database Below

Dive into the world of pressure vessel description with collection of informative blogs. Explore the intricacies of design, manufacturing, and applications for a wide range of pressure vessels, from industrial boilers to high-pressure reactors. Gain valuable insights into safety regulations, maintenance best practices, and the latest advancements in pressure vessel technology. Whether you’re an industry professional, a student, or simply curious about these critical components, our blog section offers a wealth of knowledge and resources.

Our Blog Site is still in progress. Keep checking back for more!

- See All Articles

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

Welding is a critical aspect of B31.1 piping design and construction. The ASME® B31.1 Code provides specific requirements for welding procedures to ensure the quality and integrity of piping systems.

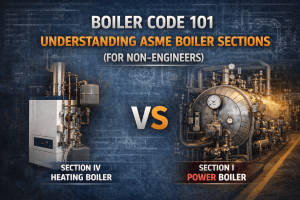

ASME boiler codes can sound intimidating, especially if you’re not an engineer by trade. The good news? You don’t need to memorize the Code to understand the basics. You just need a clear map.

Sand separators are crucial components in various industries, including oil and gas, water treatment, and manufacturing. They are designed to remove solid particles, such as sand, dirt, and scale, from liquid streams. The choice of sand separator depends on various factors, including the type...

Compact heat exchangers are a type of heat exchanger designed to provide a high heat transfer rate in a small footprint. They are commonly used in applications where space is limited, such as in aerospace, automotive, and electronics industries.

A three-phase separator is a crucial piece of equipment in the oil and gas industry, designed to separate a mixture of oil, gas, and water into its individual components. The vertical three-phase separator, equipped with a downcomer and spreader, is a particularly efficient design...

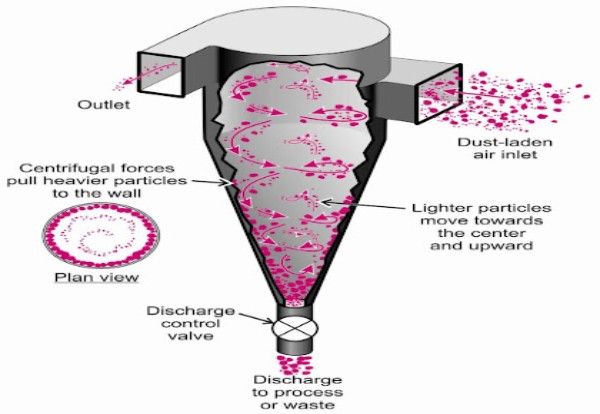

Cyclone separators are a type of mechanical separator that uses centrifugal force to separate solid particles from a gas or liquid stream. They are widely used in various industries, including mining, chemical processing, and environmental engineering.

Horizontal separators are ideally suited to wellstreams having high gas-oil ratios, constant flow, and small liquid surge characteristics. Horizontal separators are smaller and less expensive than vertical separators for a given gas capacity. Liquid particles in the wellstream travel horizontally and downward at the...

The selection of appropriate materials is a critical aspect of B31.1 piping design. The choice of material depends on factors such as temperature, pressure, corrosion resistance, and cost. By carefully selecting materials and considering the factors discussed above, engineers can design piping systems that...

In industrial operations, boiler downtime isn’t just an inconvenience—it’s a profit killer. Whether it’s lost production, emergency repair costs, or compliance penalties, a boiler failure can have far-reaching impacts. Fortunately, many of these issues are preventable with a strong, proactive maintenance strategy. In this...

Filter separators are widely used in various industries to remove solid particles from liquid streams. They are essential for maintaining product quality, protecting downstream equipment, and ensuring efficient processes.

Sand Separators. In the oil and gas industry, it is more commonly known as a separator and is a core component of extracting oil from earth and sand. Sand separators are an integral part in protecting downstream production equipment from well-formation sand and/or frac...

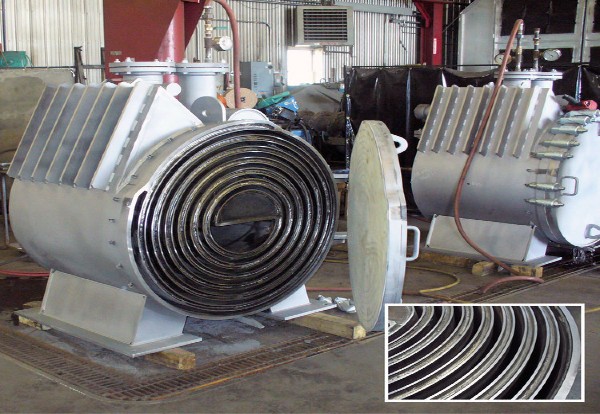

A spiral heat exchanger consists of two spiral-wound channels, one for each fluid. The two channels are separated by a partition, and the fluids flow in opposite directions through the channels. This counter-current flow arrangement maximizes heat transfer efficiency. Spiral heat exchangers are a...

Stress analysis is a critical aspect of B31.1 piping design, ensuring that the piping system can withstand the various loads and pressures it will experience during operation.

Induced draft air coolers are a type of air-cooled heat exchanger that uses fans to draw air across the finned tubes. This design offers several advantages over forced draft air coolers, including quieter operation and lower energy consumption. In an induced draft air cooler,...

Magnetic separators utilize magnetic forces to separate magnetic materials from non-magnetic materials. They are widely used in various industries, including mining, recycling, and food processing. Magnetic separators are a valuable tool for separating materials based on their magnetic properties. By understanding the principles of...

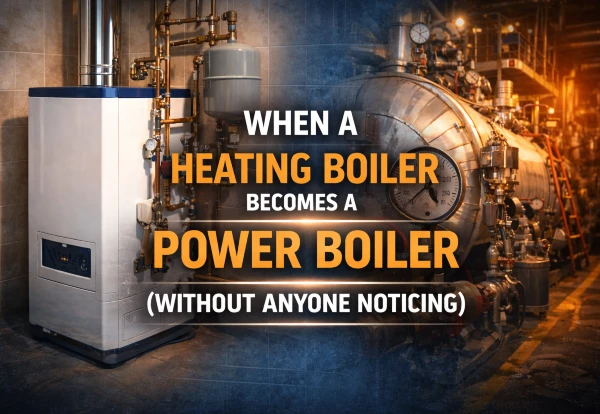

Learn how heating boilers unintentionally cross into ASME Section I power boiler classification, what inspectors look for, and how to avoid costly compliance surprises.

ASME® BPVC Section II, Part A is a critical reference document for engineers and designers involved in the construction of pressure vessels and boilers. It provides a comprehensive list of ferrous materials suitable for use in these applications.

The difference between the U designation and the UM designation is related to size. However, this is not the only difference between the two. UM designated pressure vessels are not required to undergo the same inspection regimen as the larger, U stamped pressure vessels.

An ASME® Joint Review is a rigorous process conducted by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI) to assess the quality and safety of pressure vessels and boilers.

In this must-watch episode, we break down the major updates in the 2025 edition of the ASME Boiler and Pressure Vessel Code (BPVC), released on July 1, 2025, and mandatory starting January 1, 2026. Whether you're a manufacturer, purchaser, designer, inspector, or anyone working...

A water-tube boiler is a type of boiler where water circulates inside the tubes, and hot combustion gases flow around the outside of those tubes. This design is ideal for high-pressure applications and large steam outputs, making it the go-to choice for power plants,...